Wood Refinement

When we get the wood from the sawmills we trust, it is rough and untreated. We transform it: on the band saw, with the planer and the chipper, in the steam bath and the combustion chamber, and over an open fire. At Bretter & Co, we can do exactly what you need.

Band saw finish

In the sawmill, it’s like at the barber’s or in the kitchen: you can’t get a proper cut without sharp tools. A proper saw cut from us is as neat as a new hairstyle and perfectly regular and fine. When you run your finger over a sawn-cut Mareiner board, it feels a bit rough. And that’s a good thing, because it means that the oils and glazes penetrate deeper into the wood.

The power of the band saw roughens the wood surface. This creates a regular and fine sawn-cut look.

Brushed finish

Please, where we work, the wood is as pure as the water and the people are generally pure too. So we don’t brush our boards to clean them. Rather, we do it to bring out the beautiful grain patterns even better. And to harden the boards: brushing causes the soft parts of the wood to disappear. As in real life, only the hard parts survive. The boards look more like wood than before (now purely visually) and have become more resistant as a result of brushing. A clean thing!

Burned wood finish

With wood, it is the same as with people: the strong characters have already gone through the fire once. Our charred boards undergo an intensive fire run. After that, they are brushed vigorously to bring out the wood structure. This removes the soft part of the wood – the so-called early wood. What remains is the hard late wood. And a clear emphasis of the wood structure.

Hewn finish

Long, long ago, carpenters used to shape boards and beams with their hoes (instead of planes and saws). Who still does that today? You guessed it: we do! Using a machine we developed ourselves over several years, which finishes the wood in such a lively and rustic way as in 1800. This makes each piece unique, with a one-of-a-kind structure and look, plus a rustic and Alpine character.

Sanding

Why do Mareiner boards so often end up in first-class residential and business addresses? We suspect it’s because of their polished appearance. To achieve the right finish, we use sanding brushes with different grain sizes, ranging from coarse to fine. These are used to re-sand the planed wood to a super-fine finish. This improves the adhesion of paints and varnishes and allows glazes and oils, the care lotions for the sophisticated board, to be better absorbed.

Thermal treatment

If need be, we also heat our boards properly and give the wood a real going over. With temperatures between 190 and 215 degrees and under special atmospheric conditions. But don’t go thinking we’re doing it to mess with the wood! It’s all done without chemicals and is as ecologically sound as sunbathing. Which is a good comparison, as our boards actually tan during the heat treatment and take on a darker colour. This is also healthy insofar as the wood gains in dimensional stability and durability. Hell yeah!

Wood coating

‘He who lubricates, drives,’ say the mechanics in our country. We, and of course you, will do well with our coatings. Our brushing and spraying machines apply selected, ecologically sound decking oils and glazes to the wood. This is a beauty treatment and anti-ageing cure in one, because our coatings provide new colour nuances, increase resistance and protect against greying.

Steaming

A different kind of wellness! Our wood is allowed in the sauna to steam. For three weeks at 90 degrees and a humidity level like in the tropics. After that, the boards are not only deeply relaxed, but also have a new complexion.

Planing

‘Anyone can plane,’ they say. But some make boards and others only shavings. We can make boards and also handle rough-cut pieces. The power of two precision planing machines that teach the wood manners and shape it into the desired form, or give it a decent profile.

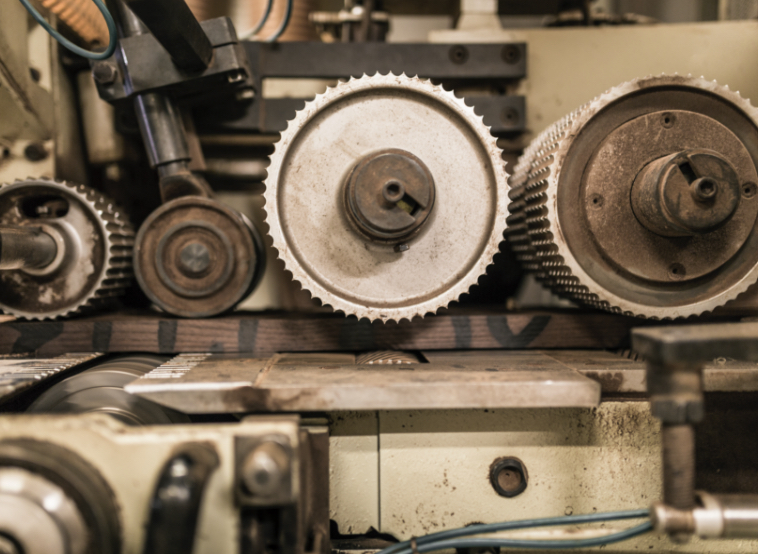

Double-end profiling

Many politicians would love to have such a high profile. You would think so. We have always been good at profiling (wood). Our voters – nonsense: our customers – appreciate this very much. Thanks to the double-end profile, our products are easy and safe to assemble. And the connections last almost forever. The double-end profiling not only enables quick and easy assembly, but also reduces waste at your construction site.

Furniture making & inlay detailing

Of course, you can find an unprocessed gem in our old wood stocks to make something beautiful for your home and hearth. For example, a kitchen worktop. But you can also get these ready-made from us: in our small carpentry workshop, we make old wooden table and worktops, as well as door blanks that will grace any household. The highlight of our carpentry team’s craftsmanship is the inlay work for the Madame Patina series: panels with geometric patterns made of different old woods.

Laminating & Pressing

Multi-layered constructions are not only a challenge for confectioners: for us wood finishers, layered boards are to us what nougat cubes and elaborate cakes are to confectioners. They are a challenge that can only be met by very precise work.

It starts with the cutting of the lamellae for the top and back layers and continues with the application of glue to the middle layer: this is checked on the scales before it goes into the press. The board is heated in the press and then subjected to a force of ten kilograms per square centimetre for ten minutes.

Milling & Drilling

Not being able to hear your own or your counterpart’s words in an open-plan office, conference room or full restaurant is one of the acoustic annoyances that people are increasingly trying to avoid. Among other things, with perforated acoustic elements that provide sound with a backstage and avoid reverberation caused by excessive reflections. How to customise the panels with a milling cutter and drill to achieve their optimum efficiency is a science in itself, which we leave to a production partner in the Waldviertel region who specialises in this.

Packaging & Storage

Now you may ask yourselves, what does packaging and storage have to do with the finishing? Quite simply: incorrect storage can cause the wood to warp and can damage its surface. That is pretty much the last thing we want. And that is why we prefer to do everything right. We also give our best when it comes to packaging and storage, with great attention to detail, so that we can deliver the finished products to you in the best possible condition and without damage.

Mareiner Custom-Tailored: Our Solution for You

Book Your Consultation Here!